Description: The induction casting furnace 2-6.3-NDG-G-2,0 / 300-N in a fixed, hydraulically tiltable version for low-pressure casting of steel, allows sand molds to be filled with liquid metal on automatic molding plants according to the low-pressure principle. The pressure control offers the possibility to fill every single mould as per desired, predetermined pressure curve.

The casting furnace consists of a ceramic-lined steel vessel with a filling siphon, a pressure chamber with a flanged crucible inductor and a pouring chamber for filling the molds. For emptying, e.g. when changing alloys, the casting furnace can be tilted hydraulically.

Technical data furnace system:

-

Capacity approx.6.5 t

-

Usable tapping weight 2.0 t

-

Total weight: 21.181 kg

-

Without liquid metal: 14.595 kg

-

Total liquid metal: 6.586 kg

-

Swamp weight: 4.500 kg

-

Usable weight: 2.086 kg

-

Tapping temperature 1600 ° C

-

Connected load 350 kVA

-

Nominal output – furnace 300 kW

-

Nominal inductor voltage 400 V

-

Frequency 80 Hz

-

Power factor 0.95 – 1.0

-

Mains supply voltage DS 400 V, 50 Hz

-

Connection voltage for auxiliary drives DS 400 V, 50 Hz

-

Control voltage WS 230 V, 50 Hz

-

Valve voltage 24 V DC

-

Spare crucible inductors: 1 pc

-

Total weight about 27.5 t

Mainly consists of:

-

Furnace body with inductor and tilt frame with hydraulic cylinder

-

Furnace li

-

Weighing scale

-

Inverter panel – Make: Otto Junker; Type: IGBT; Year 2006

-

Transformer: 350 kVA (400/750V

-

Hydraulic unit with control desk

-

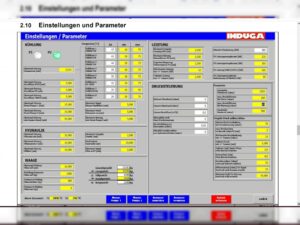

Electrical switch board and panel with PLC controls

-

Primary water cooling unit